Optimizing SMT Stencil Thickness

What Metal Thickness Should You Use for Your SMT Stencil?

Customers often ask us, “What metal thickness should I use for my SMT stencil?” There seems to be a lot of confusion about this issue, no doubt due to the fact that there is no hard-and-fast answer. There’s the 1.5 Ratio…but there are also exceptions to that standard.

Customers often ask us, “What metal thickness should I use for my SMT stencil?” There seems to be a lot of confusion about this issue, no doubt due to the fact that there is no hard-and-fast answer. There’s the 1.5 Ratio…but there are also exceptions to that standard.

What you need to know:

- Start by looking at your assembly’s smallest feature – What is the smallest pitch on the board that you’re trying to assemble, or the smallest aperture needed on the smt stencil? People often start by looking at the whole assembly that they’re working with, and then get confused trying to bridge a gap that isn’t actually important. The best solution is to start by looking at the smallest feature, figure out what metal thickness you need to accommodate that feature, and know that you’ll have the latitude to make adjustments from there.

- Make your calculations using the “1.5 ratio” – The basic idea is that the ratio of the size of the smallest feature vs. the thickness of the metal shouldn’t be less than 1.5. So, for example, if your smallest feature is a 9 mil aperture, then your metal thickness should be 6 mil.

- Adjust for available metal thicknesses – But what if your smallest feature is a 10 mil aperture? Using the 1.5 ratio gives you a metal thickness of 6.6 mil. However, since metal is not made in this size, in this situation you would use a foil that is 6 mil thick since 7 mil metal is not readily available.

- Adjust for type of paste being used – The type of paste being used is related to the size of the template’s smallest aperture. If you ran your numbers based on the smallest aperture size, you probably already accounted for the paste. But if you started by looking at pitch, a minor adjustment might be needed.

How I-Source Can Help:

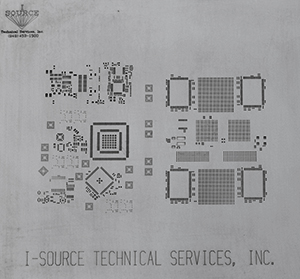

Over the years we’ve worked very closely on specialized smt stencil thicknesses, including producing smt stencils in very non-standard/unique thicknesses that worked out extremely well.

With the ability to design and manufacture smt stencils in specialized thicknesses I-Source is often able to support clients that other suppliers could not. This opens a wealth of new possibilities not only to the client, but to the consumer as well. By possessing the capacity to alter smt stencil thickness, companies have the ability to continually push the bounds of what is possible in the electronics manufacturing world. By removing restrictions in manufacturing, innovation continues to grow and thrive.

Specialized smt stencil thickness grants the user to do things not possible before.

Still not sure what metal thickness to use?

Give us a call. We have the expertise to help you make the best decision based on your specifications.