CAPABILITIES

For A Broad Range of Custom Parts

Capabilities at I-Source include laser manufacturing, low volume prototype manufacturing, shadow masks for vapor deposition, and laser & CNC tooling and fabrication. We manufacture a broad range of precision assembly parts. Whether you need to replace a simple component, or rework assembly for complex package-on-package stacks, we’re equipped to respond to the changing needs of customers daily.

Before quoting your project, I-Source engineers always review your design for manufacturability and choose the most appropriate laser system to micromachine your parts, based on feature sizes, tolerances, volume, and material. We support you until we are certain your part can be built for success. Keep reading for more about our custom manufacturing capabilities.

PRECISION LASER &

CNC MICROMACHINING

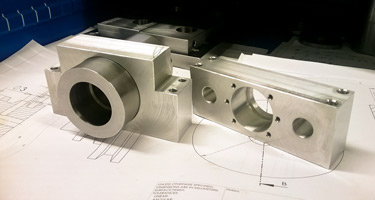

I-Source offers a range of cost-effective and highly repeatable laser and CNC micromachining capabilities for applications ranging from prototyping, production manufacturing, milling, cutting, engraving, and welding. Using the latest machinery and software, we provide 3rd, 4th and even 5th axis tight-tolerance machining services, and can quickly produce parts, models, fixtures, and tools for short-run and low-volume quantities.

I-Source offers a range of cost-effective and highly repeatable laser and CNC micromachining capabilities for applications ranging from prototyping, production manufacturing, milling, cutting, engraving, and welding. Using the latest machinery and software, we provide 3rd, 4th and even 5th axis tight-tolerance machining services, and can quickly produce parts, models, fixtures, and tools for short-run and low-volume quantities.

The advantages of laser processing include fast, inexpensive prototype parts, little or no tooling, and intricate close tolerance cut features. I-Source has produced parts in a broad range of metals such as: aluminum, brass, copper, Kovar, Invar, molybdenum, nickel, Nitinol, platinum iridium, titanium, tungsten, stainless steel & more, and we routinely process components in advanced composite materials like polyester, ceramic and fiberglass. See Our Materials List.

Milling

We offer CNC vertical milling with 3-5 axis machines using a wide array of materials, and we’re able to run large-sized items up to 30″ x 70″. Our manufacturing specializes in quick-turn prototyping and innovative design assistance.

Welding

We offer tig/mig and stick welding on a broad range of thicknesses. Our welding capabilities include materials like aluminum, steel, stainless steel and most standard materials, ranging from .5″ thick steel plates to 1″ Aluminum plates. We also offer welding services for rework and repair.

Finishing

After we manufacture your part, we use a variety of finishing processes to ensure that your part is clean, burr-free and ready to stand up to use. Finishing services include cleaning, chemical coating, painting, priming, chemical micro-etching, nano coating, de-burring, electro polishing and/or sand blasting.

TOOLING & ASSEMBLY

Our tooling engineers utilize over 30 years of experience in creating custom fixtures, parts and systems to maximize efficiency and productivity. All parts are fabricated in-house on state-of-the-art laser and/or CNC machines, resulting in very accurate dimensional accuracy.

Our tooling engineers utilize over 30 years of experience in creating custom fixtures, parts and systems to maximize efficiency and productivity. All parts are fabricated in-house on state-of-the-art laser and/or CNC machines, resulting in very accurate dimensional accuracy.

From routine component changes, to IPC Level 3 soldering, we help keep your project moving. Our teams will rework your existing boards to solve manufacturing issues for faulty units, and we can reball your BGAs allowing you to salvage even the most sensitive components and irreplaceable boards. We use only the best tools available so there’s no need to recruit staff or procure equipment.

All of our custom fixtures and tooling are designed and manufactured by our CNC programming engineers on site at our Orange County, California facility. If your facility is located within 100 miles of ours, we can pick up your circuit board to facilitate the design process or help you work out challenges on your in-house assembly.

Some Of The Tooling & Assembly We Create Every Day At I-Source:

RAPID PROTOTYPING

When your device is designed to be easily manufactured and reliable in the field, it’s more likely to be successful in the market: producing your prototype with I-Source can make your project more profitable.

When your device is designed to be easily manufactured and reliable in the field, it’s more likely to be successful in the market: producing your prototype with I-Source can make your project more profitable.

We offer unbeatable turnaround on prototyping via additive manufacturing (3d printing), laser cutting and cnc milling to provide you with quick design knowledge allowing you set your ideas into motion fast.

Because prototype development is so critical to successful product manufacturing, our engineers work closely with you to recognize and address design problems before they emerge, preventing costly redesigns or delays. We can provide you with collaborative engineering to assist with the design of your part or material, and you’ll have direct access to our engineering expertise including Design for Manufacturability DFM to ensure the plausibility and efficiency of your part right from the start. As you move from experimentation to full-scale manufacture, the I-Source engineers move with you. Get Technical Advice (877) 697-8362

DESIGN FOR MANUFACTURING

Well-Designed And Well-Built

Design for Manufacturing (DFM) also known as Design for Manufacturability evaluates the various factors which can affect manufacturability and cost, such as raw material, dimensional tolerances and secondary processes like finishing. It is during this process where potential design problems are found and fixed, and where the analysis of the design of components reveal opportunities to reduce costs and improve efficiency.

Design for Manufacturing (DFM) also known as Design for Manufacturability evaluates the various factors which can affect manufacturability and cost, such as raw material, dimensional tolerances and secondary processes like finishing. It is during this process where potential design problems are found and fixed, and where the analysis of the design of components reveal opportunities to reduce costs and improve efficiency.

DFM is an integral part of our precision manufacturing process at I-Source, and we can quickly manufacture pre-production prototype components while providing input throughout the design phase, helping our OEMs design products that are high quality and easy to manufacture.

We’re capable of working with all types of materials (metals, plastics, and composites), have laser and CNC equipment available for prototyping prior to production of cutover and prototype assemblies. We can analyze your PCB manufacturing cycle, then recommend specific components or assembly processes that decrease costs and production time, saving money and enhancing the finished product.

We’re able to work from blueprint, spec. or solid models and we provide fit, form, and function on-site at your facility.

Need Help Solving A Problem In Your Production Line?

Our engineers can come out to your shop and provide recommendations to help you stay efficient and cost-effective.

Don’t have a design yet?

No problem. We can help you explore and design modern, cost-effective tooling and assemblies to manufacture your products. Just reach out to us and we’ll connect you with one of our experienced engineers. If you’re located in Los Angeles or Orange County, we’ll even come out to your facility and evaluate the possibilities of your production line.