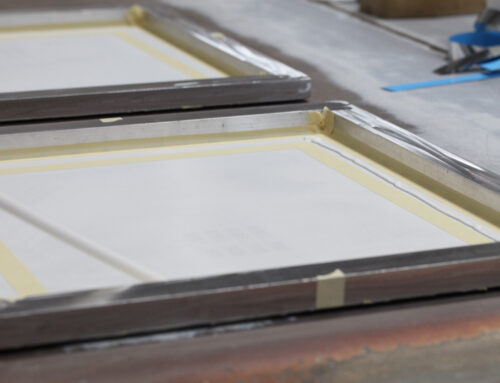

Enhanced Paste Release For SMT Stencils

I-Source knows how complex SMT printing can be. There are always a variety of factors that affect the functionality and ease of use of an SMT stencil. Our goal is to help make the process go as smoothly as possible. To do this, we have created a number of Enhanced Paste Release Solutions to allow for your SMT stencil to work at its best.

Micro-Etching (Formerly the ‘Slick Stencil Process’)

Is a unique chemical process developed at I-Source that creates a glass-like surface within the aperture wall. This makes it easier for the paste to slide through the aperture. This process is most beneficial when printing stencils with a high number of small apertures.

Nano Coating

A chemical wipe that coats the stencil to:

- Enhance paste release

- Reduce cleaning frequency during the printing process

- Provide better quality printing

EPR (Enhanced Paste Release Solutions)

These three options are available to help create highly efficient SMT stencils:

- EPR 1 – The stencil is nano coated.

- EPR 2 – The stencil apertures are micro-etched.

- EPR 3 – The stencil is nano coated and micro-etched.

We Can Help You Decide

Which of these processes is best for you. With some of these processes being proprietary to I-Source Technical Services we are granted a unique understanding of their uses and benefits. We can help you select the correct EPR for your stencil.

We’re readily awaiting your call! (877)697-8362